The Istituto Italiano della Saldatura Group (IIS Group) boasts the availability of a of highly specialized and multidisciplinary technicians’ team that grows and lives breathing the air of a Company, the IIS Group itself, which has in the last 70 years the fundamental mission, to support its customers in the various Industry fields.

Therefore, the IIS Group, within its Laboratory division and in real-time collaboration with its other specialized technical divisions, can represents a single Go-To reference to better clarify all the aspects connected to the failure of a component (how and why) and to define actions that can potentially be implemented as lesson learnt after the event of failure (corrective actions).

The in-depth approach of IIS to failure and root causes analysis studies is supported by a robust knowledge of Codes, Standards, Regulations applicable around the Industry.

>> The mechanisms

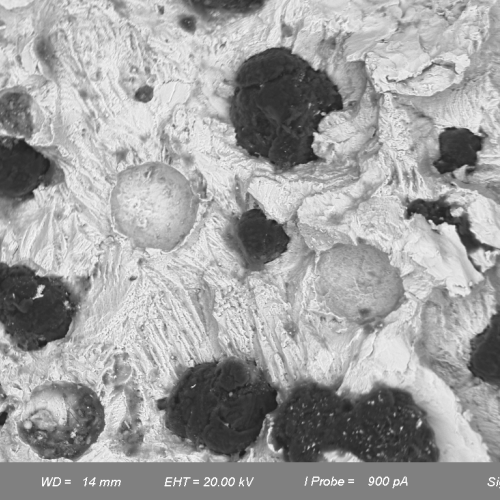

The most common damage modes/mechanisms that IIS failure analysis team faces every day include as “best seller”:

- Mechanical damages

- Generalized corrosion

- Localized corrosion

- Stress Corrosion Craking (SCC)

- Microbiologically Corrosion (MIC)

- Fatigue/Corrosion Fatigue.

>> The main causes

The origin (physical and root causes) of a bad event can be recognized in different phases of component life and at different levels of hierarchy of causes, each characterized by specific barriers against possible “failure”.

- Design

- Fabrication (e.g. welding, forming...)

- Service

- Maintenance

- Knowledge

- Organization.

>> In case of failure event

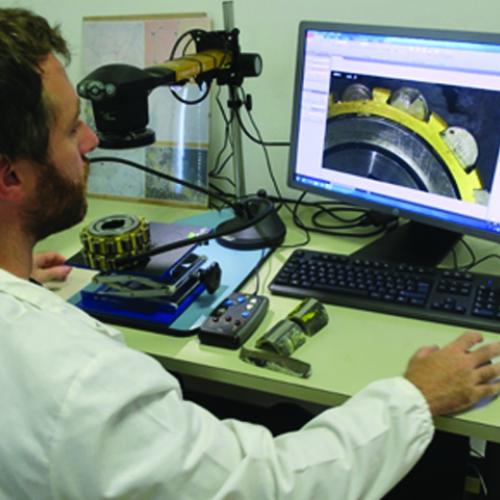

…a site inspection as timely as possible in the failure analysis process can be a focal point for first-rate results.

- Site inspection

- Interviews & data collection

- Samples identification

- Metallographic replica

- Fractographic replica

- Positive Material Identification (PMI)

- Non-Destructive Examination (NDE).