The protection systems of industrial plants, against excessive pressure, are one of the key elements to ensure the safety of production processes for the population incolumity and health and for the environmental protection.

The protection of industrial plant is generally entrusted to devices for direct pressure limitation, the so-called safety valves (PSV - Pressure Safety Valve) or rupture discs (RD), or accomplished by systems / safety chains (SRMCR - Safety Related Measurement Control and Regulation) which, through the safety Instrumented systems (SIS - Safety Instrumented System) are able to ensuring the required safety levels.

With reference to the devices for direct pressure limitation, IIS SERVICE provides the following services:

- PSV and RD sizing evaluation in compliance with EN ISO 4126, API 520/521, ISPESL Raccolta E

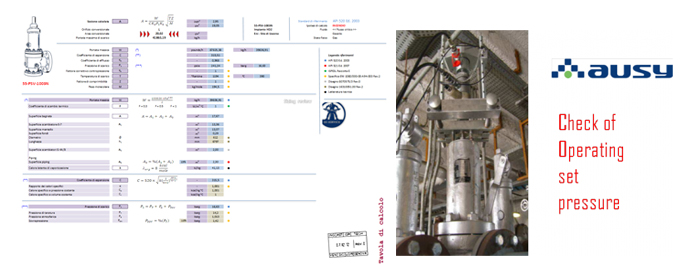

- Assistance for PSV shop check of operative set pressure in compliance with API 526/527

- PSV in operation: check of operative set pressure by means of the PSV Monitor equipment (hydraulic jacks type) according to UNI 11513

- PSV inspection and assistance for pre-pop test according to API 576

- PSV relieving capacity evaluation, relating to modifications defined by HAZard and OPerability (HAZOP) analysis, or because of variations on base calculation assumptions or modification on the protected equipement

- PSV failure analysis

- PSV Risk Based Inspection analysis according to the API-RBI Technology with reference to the Recommended Practice 581.

As far as the SRMCR (Safety Related Measurement Control and Regulation) is concerned, IIS SERVICE provides the following services:

- SIL (Safety Integrity Level) allocation, in compliance with IEC 61508/61511. IIS SERVICE carries out the evaluation of the integrated safety level required for the system or industrial plant, in order to mitigate the risk level to the tolerable value defined by an ALARP (As Low As Reasonably Practicable) approach. The most proper architecture for the system together with the definition of the reliability minimum requirements for each chain element are identified

- SIL (Safety Integrity Level) verification, in compliance with IEC 61508/61511. IIS SERVICE is able to verify the actual SIL level, based on the installed elements of each Safety Instrumented System (SIS).